Project Description

OTHER PRODUCTS

Dust Conditioner

Dust Conditioner is used to mix dust in powder form with water in order to fix the dust. It is the most economic, advanced technology dust processing equipment that is very easy to install and use.

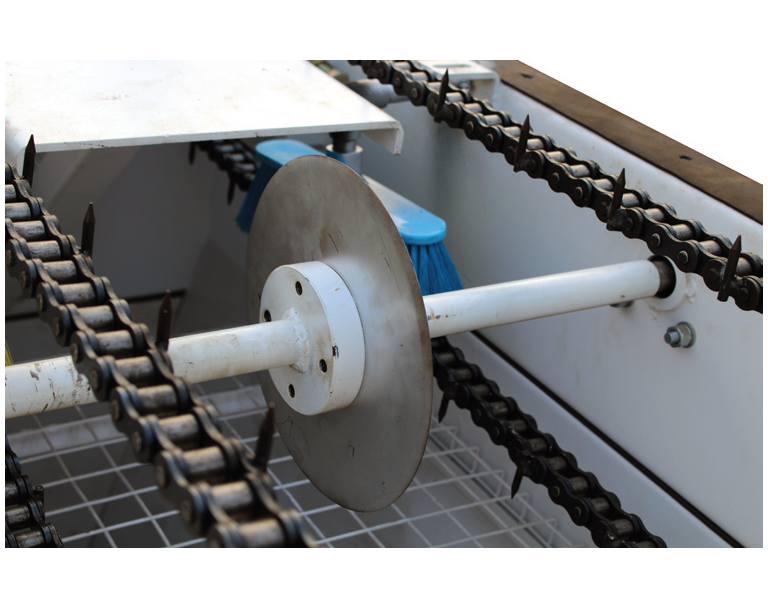

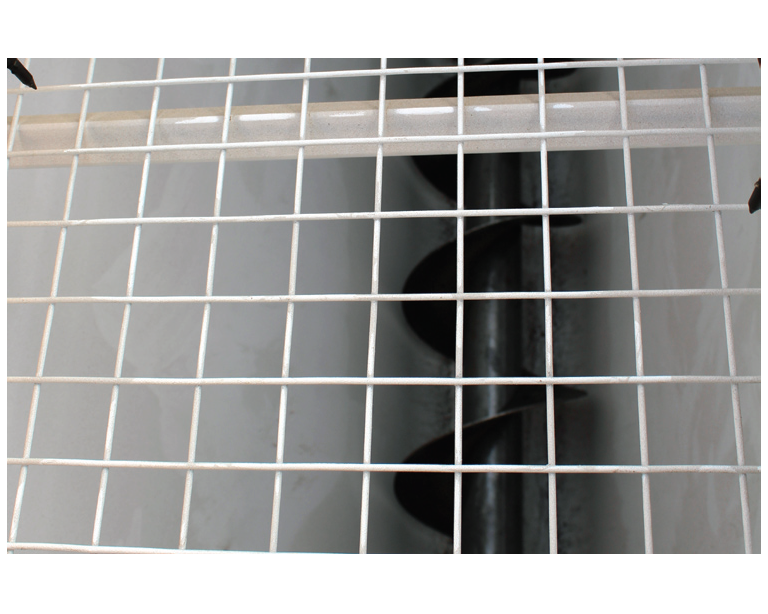

The dust conditioner is divided in two parts. First part is a screw feeder and the second part is a mixer.

The mixer has heavy duty internal screw with replaceable ploughs made up of hardox material which are specially designed to mix the powder with water. These ploughs are used for both non-abrasive and highly abrasive type of powder There are sprinkler nozzles with ball valve to conveniently adjust the water flow.

Speed – 145rpm. Capacity – 22 m3/hr

Working Principle

- The bag is manually loaded on to the moving belt conveyor.

- The bag moves up and goes in the cutting area where a high speed rotating cutter slits the bag in the center – length wise

- The material falls down in to the collecting area and is conveyed to the outlet by the screw conveyor

- The empty bag travels through the machine and there will be no residue remaining in the bag as the empty bag moves out of the machine.

Two Options available to convey the material into the silo

- First option: – at the out let of bag cutting machine (screw conveyor outlet), a blow through and pressure proof rotary valve is fitted. The twin lobe blower can blow the material in the silo

- Second option – a vertical screw conveying system can be fitted at the outlet of bag cutting machine (Screw conveyor outlet)

FREE QUOTE

Do you need help? Fill out this form to get in touch.

info@globalbmsol.com

Call Now

+91 9886600903

info@globalbmsol.com

Call Now